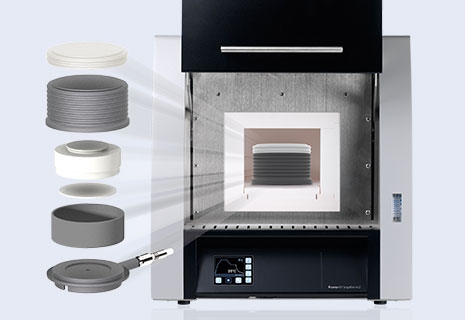

The CoCr sintering furnace Ceramill Argotherm 2 is an integral part of a system with optimally coordinated components for processing the sinter metal Ceramill Sintron. Only the perfect adaptation of sinter metal, processing in the CAD/CAM system and completion in the sintering furnace ensure consistently high material quality – especially if it involves the mechanical properties and (micro-) structure of the finished restoration. Easy to operate at the press of a button, the Ceramill Argotherm 2 controls the sinter programme of the milled CoCr units.

The “core” of the system, the removable Ceramill Argovent sinter chamber, ensures minimal consumption of argon gas and homogeneous, distortion-free sintering of the restorations.

Fitted with a touchscreen and a clearly structured display for the optical control of the sintering process, the Argotherm 2 offers greater convenience in terms of operation and handling. The compact furnace with minimum space requirements is used as a table-top model and cools down actively after sintering.

Sintering program developed specifically for Ceramill Sintron

A validated system guarantees consistent high quality of the results

Active cooling after the sintering process

Minimal consumption of protective gas

Sintering at the push of a button – extremely easy operation with touch screen technol-ogy

USB interface for program updates and log files for monitoring firing

You may also like…

-

Easy Fix

65,00 JOD -

Furnace Ceramill® Therm DRS

13.000,00 JOD